S3(t) Double-wall flame-retardant polyolefin heat shrinkable tubing

Keywords:

S3(t) Double-wall flame-retardant polyolefin heat shrinkable tubing

Category:

Heat shrink products in military and aerospace fields

Hot-line:

Details

| Introduction | ||||

| A thin-walled, soft, flame-retardant, double-walled polyolefin heat-shrinkable tube with adhesive is used for parts or parts of military equipment that need to be waterproofed and sealed, and can be widely used for sealing and moisture-proof protection of cable end connectors or electronic components. | ||||

| Features | |

| Operating temperature: -55~110 ℃ | |

| Minimum full shrinkage temperature: 125 ℃ | |

| Shrink ratio: 3:1 & 4:1 | |

| GJB 7283-2011 compliant |

| Technical data | ||||

| Property | Test Method | Value | ||

| Longitudinal change rate | GJB 7283-2011 | -15%~1% | ||

| Restricted shrinkage(150℃/30m) | GJB 7283-2011 | No cracks on the surface | ||

| Water absorption (23℃/24h) | GJB 7283-2011 | ≤1.0% | ||

| Tensile Strength | GJB 7283-2011 | ≥9.0MPa | ||

| Breakdown elongation | GJB 7283-2011 | ≥250% | ||

| Tightness | GJB 7283-2012 | After heat fusion sealing, there is no air leakage at the heat fusion joint | ||

| Heat shock(250℃/4h) | GJB 7283-2011 | No cracks, no flow, no drips on the surface | ||

| Aging (175℃/168h) Exterior |

GJB 7283-2011 | No cracks, no flow, no drips on the outer wall |

||

| Dielectric strength | GJB 7283-2011 | ≥11.8kV/mm | ||

| Insulation withstand voltage (AC2500V·1min.) |

GJB 7283-2011 | No breakdown | ||

| Volume resistivity | GJB 7283-2011 | ≥1.0×1012Ω·cm | ||

| Liquid resistance(23℃/24h) Tensile Strength Dielectric strength |

GJB 7283-2011 | ≥ 6.2MPa ≥ 7.9kV/mm |

||

| Flame retardant | GJB 7283-2011 | The continuous burning time after leaving the fire does not exceed 60S | ||

| Copper corrosion(121℃/16h) | GJB 7283-2011 | No dents or blackening on the copper surface | ||

| Low temperature flexibility (-55℃/4h) | GJB 7283-2011 | No cracks on the surface | ||

| High and low temperature impact(-55℃/110℃) | GJB 7283-2011 | No cracks, no flow, no drips on the outer wall | ||

| Salt spray | GJB 150.11 | No cracks, no flow, no drips on the outer wall | ||

| Damp heat | GJB 150.9 | No cracks, no flow, no drips on the outer wall | ||

| Mold | GJB 150.10 | The degree of mold growth is not inferior to level 1 | ||

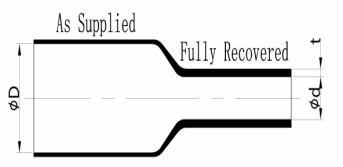

| Dimension | |||||

| Size | As Supplied(mm) | After shrink (mm) | Wire mass(Max.) | Standard length | |

| S3(t) | Inner Diameter(Min.) | Inner Diameter (Max.) | Wall thickness | g/m | m |

| Shrink ratio 3:1 | |||||

| 3/1 | 3 | 1 | 1.00±0.28 | 0.50 | 8.0 |

| 4.8/1.6 | 4.8 | 1.6 | 1.00±0.28 | 0.50 | 13.6 |

| 6/2 | 6 | 2 | 1.00±0.28 | 0.50 | 15.5 |

| 9/3 | 9 | 3 | 1.40±0.28 | 0.61 | 22.2 |

| 12/4 | 12 | 4 | 1.78±0.38 | 0.76 | 40.0 |

| 18/6 | 19 | 6 | 2.25±0.55 | 0.76 | 75.3 |

| 24/8 | 24 | 8 | 2.54±0.55 | 1.02 | 91.2 |

| 39/13 | 40 | 13 | 2.54±0.55 | 1.02 | 135.6 |

| Shrink ratio 4:1 | |||||

| 4/1 | 4 | 1 | 1.00±0.28 | 0.50 | 11.8 |

| 8/2 | 8 | 2 | 1.00±0.28 | 0.50 | 16.0 |

| 12/3 | 12 | 3 | 1.40±0.28 | 0.61 | 34.4 |

| 16/4 | 16 | 4 | 1.78±0.38 | 0.76 | 43.5 |

| 24/6 | 24 | 6 | 2.25±0.55 | 0.76 | 73.0 |

| 32/8 | 32 | 8 | 2.54±0.55 | 1.02 | 96.0 |

| 52/13 | 52 | 13 | 2.54±0.55 | 1.02 | 146.5 |

| Ordering instructions: Please order according to "model-specification-color", such as S3(t)-12/4-0 | |||||

| Color: black (-0), brown (-1), red (-2), orange (-3), yellow (-4), green (-5), blue (-6), purple ( -7), gray (-8), white (-9), pink (-P), brown (-T), etc. | |||||

| Color code: black (-0), brown (-1), red (-2), orange (-3), yellow (-4), green (-5), blue (-6), purple (-7) , Gray (-8), white (-9), pink (-P), brown (-T), transparent (-X) | |||||

| Cross reference | |

| Raychem/TE:ATUM |

Product diagram

Related products

Messages