S13 Low Vacuum Outgassing Radiation Resistant Heat Shrink Tubing

Keywords:

S13 Low Vacuum Outgassing Radiation Resistant Heat Shrink Tubing

Category:

Heat shrink products in military and aerospace fields

Hot-line:

Details

| Introduction | |||

| A soft irradiation cross-linking modified polyolefin heat shrinkable tube has radiation resistance, low heat vacuum outgassing, softness and flame retardancy. It is used for the protection and connection protection of components in aerospace equipment in military equipment, effectively achieving radiation resistance performance and avoiding the release of small molecules and weight loss in low vacuum environments. | |||

| Features | |

| Operating temperature: -55~135 ℃ | |

| Minimum full shrinkage temperature: 125 ℃ | |

| Shrink ratio: 2:1 | |

| GJB 1217A-2009 compliant |

| Technical data | ||||

| Property | Test Method | Value | ||

| Longitudinal change rate | GJB 7270-2011 | -5%~5% | ||

| Restricted shrinkage(175℃/30m) | GJB 7270-2011 | No cracks on the surface | ||

| Water absorption (23℃/24h) | GJB 7270-2011 | ≤0.5% | ||

| Tensile Strength | GJB 7270-2011 | ≥10.4MPa | ||

| Breakdown elongation | GJB 7270-2011 | ≥200% | ||

| 热冲击(250℃/4h) | GJB 7270-2011 | No cracks, no flow, no dripping on the surface | ||

| Aging(250℃/168h) Tensile Strength Breakdown elongation |

GJB 7270-2011 | ≥70% of the initial value ≥100% |

||

| Dielectric strength | GJB 7270-2011 | ≥19.7kV/mm | ||

| Insulation withstand voltage (AC2500V·1min.) | GJB 7270-2011 | Not broken down | ||

| Volume resistivity | GJB 7270-2011 | ≥1.0×1014Ω·cm | ||

| Liquid resistance(23℃/24h) Tensile Strength Breakdown elongation |

GJB 7270-2011 | ≥70% of the initial value ≥100% |

||

| flame retardancy | GJB 7270-2011 | The continuous burning time does not exceed 60S after leaving the fire | ||

| Copper corrosion(175℃/16h) | GJB 7270-2011 | No dents or blackening of the copper surface | ||

| low temperature flexibility(-55℃/4h) | GJB 7270-2011 | No cracks on the surface | ||

| High and low temperature impact(-55℃/135℃) | GJB 7270-2011 | ≥70% of the initial value | ||

| Breakdown elongation≥100% | ||||

| salt spray | GJB 150.11 | Tensile Strength ≥70% of the initial value Breakdown elongation ≥100% |

||

| damp heat | GJB 150.9 | Tensile Strength ≥70% of the initial value Breakdown elongation ≥100% |

||

| mold | GJB 150.10 | The degree of mold growth is not worse than grade 1 | ||

| Thermal vacuum outgassing | GJB1217A-2009,method 4001 | TML≤1% CVCM≤0.1% |

||

| Radiation resistance | GJB178A,method 1019 | The irradiation dose is 200krad (Si), and the surface is free from cracks, damage and brittleness | ||

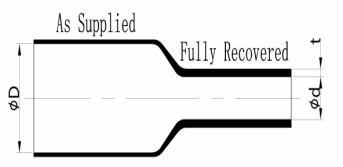

| Dimension | |||||

| Size | As Supplied(mm) | After shrink (mm) | Wire mass(Max.) | Standard length | |

| S13 | Inner Diameter(Min.) | Inner Diameter (Max.) | Wall thickness | g/m | m |

| 1.5/0.8 | 1.5 | 0.15±0.10 | 0.8 | 0.30±0.08 | 200 |

| 2.4/1.2 | 2.4 | 0.15±0.10 | 1.2 | 0.30±0.08 | 200 |

| 3.2/1.6 | 3.2 | 0.15±0.10 | 1.6 | 0.30±0.08 | 200 |

| 4.8/2.4 | 4.8 | 0.15±0.10 | 2.4 | 0.30±0.08 | 200 |

| 6.4/3.2 | 6.4 | 0.20±0.10 | 3.2 | 0.40±0.08 | 200 |

| 9.5/4.8 | 9.5 | 0.25±0.10 | 4.8 | 0.50±0.08 | 100 |

| 12.7/6.4 | 12.7 | 0.30±0.10 | 6.4 | 0.60±0.08 | 100 |

| 19.1/9.5 | 19.1 | 0.35±0.10 | 9.5 | 0.70±0.08 | 100 |

| 25.4/12.7 | 25.4 | 0.40±0.12 | 12.7 | 0.80±0.12 | 50 |

| 31.8/15.9 | 31.8 | 0.45±0.12 | 15.9 | 0.90±0.12 | 50 |

| 38.1/19.1 | 38.1 | 0.50±0.15 | 19.1 | 1.00±0.15 | 50 |

| 50.8/25.4 | 50.8 | 0.55±0.15 | 25.4 | 1.10±0.15 | 50 |

| Ordering instructions: please order by "model-specification-color", such as S13-9.5/4.8-0 | |||

| Color: Black (-0), white (-9), transparent (-X) should be used |

Product diagram

Related products

Messages